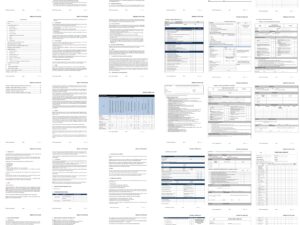

Purpose:

To ensure the safety of personnel and property during hot work activities by identifying and mitigating potential hazards.

Key Elements:

- Potential Hazards Considered:

- Fire risk

- Electricity hazards

- Manual handling

- COSHH (Control of Substances Hazardous to Health)

- Environmental risk

- Persons at Risk:

- Employees

- Subcontractors

- Visitors

- General public

- Mandatory Health, Safety, and Environment (HSE) Requirements:

- Safety induction

- Tool box talks

- Proper PPE (Personal Protective Equipment)

- Work permit

- Proper tools and equipment

- Proper supervision

- Barricades and warning signs

- PPE Requirements:

- Safety helmets

- Safety boots

- Goggles/spectacles

- Gloves

- Masks

- Overalls

- Ear plugs/defenders

- Respiratory/breathing apparatus

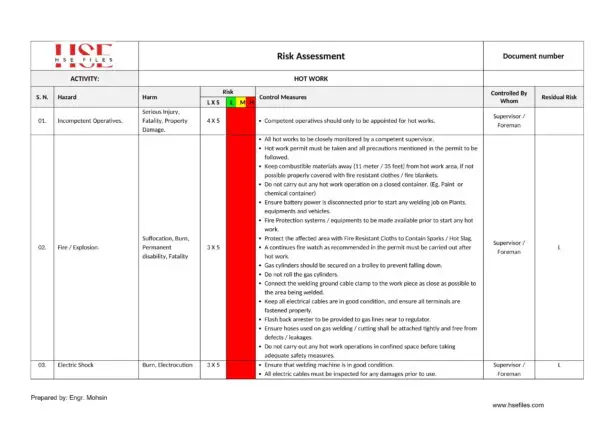

- Risk Levels and Control Measures:

- Incompetent Operatives: Ensure only competent operatives perform hot work.

- Fire/Explosion: Monitor hot works, obtain permits, keep combustible materials away, and ensure fire protection systems are in place.

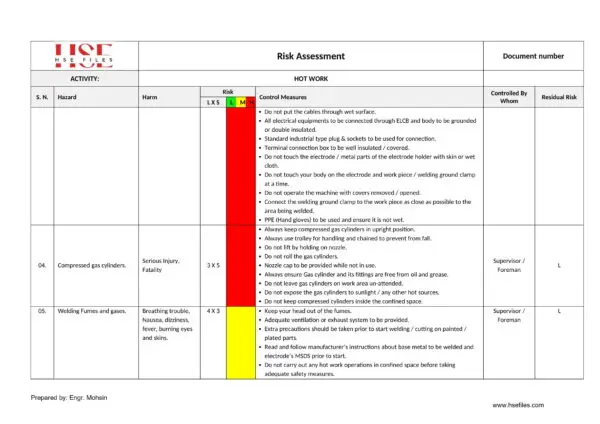

- Electric Shock: Use well-maintained equipment, inspect cables, avoid wet surfaces, and ensure proper grounding.

- Compressed Gas Cylinders: Keep cylinders upright, secure them, avoid rolling, and do not expose to heat.

- Welding Fumes and Gases: Ensure proper ventilation, follow manufacturer’s instructions, and use appropriate PPE.

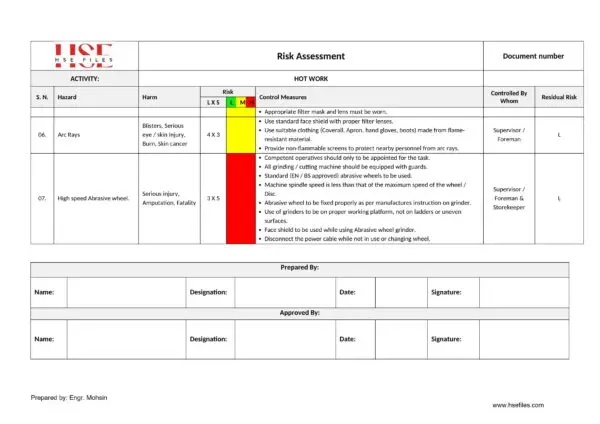

- Arc Rays: Use proper face shields and flame-resistant clothing, and provide non-flammable screens.

- High-Speed Abrasive Wheel: Use guards, standard abrasive wheels, and ensure proper machine spindle speed. Use face shields and disconnect power when not in use.

Ongoing Process:

Risk assessment is a continuous process and must be communicated to workers before starting the job. It is regularly reviewed to adapt to new activities and potential risks, ensuring a safe working environment.

Hot Work Risk Assessment: The attached document is a powerful tool for identifying and mitigating risks associated with hot work activities in your workplace and site. It’s more than just a form—it’s a proactive step toward safety excellence.

Hot Work Risk Assessment: The attached document is a powerful tool for identifying and mitigating risks associated with hot work activities in your workplace and site. It’s more than just a form—it’s a proactive step toward safety excellence.

Reviews

There are no reviews yet.